If you are among off-roading enthusiasts who love to take their 4WD away from the concrete buildings and asphalt-built roads to feel a sense of adventure that mundane city life has deprived us of, then you must always be looking for equipment that would further enhance your ability to maneuver rocky and rough terrains. Why not, after pursuing this beautiful hobby brings so many joyful memories for us.

Off-roading can be done anywhere whether it’s on beaches, mountains, or rugged terrain.

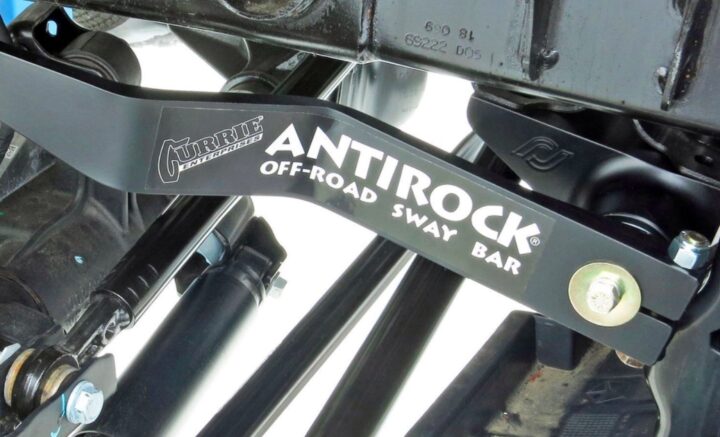

An antirock sway bar- that’s the technical term. It’s also called a sway bar, anti-sway bar, or stabilizer bar. It’ll keep your SUV from getting too wobbly on the road when you’re hitting bumps and potholes.

You know what I’m talking about: your car bounces up and down like it has no springs in it at all! The only thing is, if you have an SUV with really low clearance (or even worse–no clearance), then installing one of these babies may be tricky for you because most models require some space underneath to fit correctly.

This post will help answer any questions you might have about this awesome piece of machinery that can make your ride more comfortable while also boosting its performance on and off the road.

I’m going to start by giving advice about how to pick your anti-sway bar depending on what kind of car you have. I’ll also give you some options for where you can find them if they don’t stock them in stores near you. Then, I’ll go ahead and tell you which one to get if you drive a 2WD truck.

I’ll go ahead and note that this post is not about sway bars for 4WD trucks, so I won’t be talking about them in any detail. Just know that some of the same rules apply but most of them will NOT fit onto your vehicle with only minor adjustments. There are certain modifications that you will have to make to your truck if you want it to handle correctly after attaching one, and I’m not going to cover them in this post.

One such extreme forum that is off-roading is Rock-crawling. Rock crawling, where one overcomes massive rocks, often pushes the car’s mechanical limits to the extreme. Standard sway bars that are installed on factories are usually not capable enough to provide you the best driving experience on such uneven off-roading expeditions bringing in the need for an antirock Sway bar.

A lot of offroading junkies are still not aware of what an antirock sway bar is, why it is needed and how it works. In this article, we would ensure that your questions are answered and you can make a decision as to whether to install it or not.

Table of Contents

What Does An Antirock Sway Bar Do?

The inbuilt sway bars are installed to connect the body to the rest of the frame so that while driving or taking a turn, the vehicle doesn’t roll towards one side ensuring safety.

But the disadvantage of sway bars comes up when one is off-roading as it keeps the body of the vehicle connected to the frame, limiting its ability to flex on rocks.

So, most off-roaders would disconnect their sway bars while off-roading to be able to flex. For this one has to move under the vehicle to disconnect and connect back while the adventure trip is done which is a hassle in itself esp. when the vehicle is covered with mud.

Anti-Rock Sway bars would ensure that you don’t have to go through this process of disconnecting or connecting them as they are connected all the time while also giving you almost the same flex of disconnected sway bars. They also give the safety from rollover while taking the turns just like sway bars.

The need for an antirock sway bar arose when Jeep wrangler owners realized while off-roading the front sway bar would disconnect completely and only run the rear sway bar. And if the Jeep didn’t run any sway bar, they would behave so much body roll that it would become dangerous to drive.

So, there was a need for balance between the front and rear sway bar and this is where the antirock sway bar comes into play.

It’s important to know how the antirock sway bar works to get a better understanding of the benefit one would get while off-roading.

How Does The Antirock Sway Bar Work?

An antirock sway bar also referred to as a torsion bar, is specifically designed for off-roading purposes with the purpose of higher flexibility and chassis control. It works along with rear sway bars keeping them connected at times resulting in an even distribution of forces on the front and rear axles.

An antirock sway bar would make sure that if the front wheel would lift 6 inches in the air, the rear diagonally opposite wheel would go down 6 inches and vice versa. This makes rock-crawling so much easier as the tires would coordinate amongst themselves ensuring traction and balance of the car.

Antirock sway bar assists in providing increased traction to all four tires as they ensure equal distribution of weight and increased balance. Both the front and rear suspension are balanced resulting in better performance on off-roading conditions.

This results in greater traction reducing body sway during side slope and off-camber situations much easier to deal with.

Once the anti-rock sway is installed, there is no need for further interference. You don’t have to do any pin pulling or tie sway bar while off-roading. Though usual stop to air-down the tires is recommended.

Otherwise, getting off the jeep covered with mud to hook things back would be a real pain. Anti-rock sway bars are easy to install, transparent, and built with fit-and-forget purpose.

What Are Some Antirock Sway Bar Styles?

If you don’t know which type of sway bar (or anti-sway bar) is right for you, here are all of the options and the kinds of cars they’re good for:

The Z Bar

Also called the triangulated or A-frame, it will fit any car with a solid axle upfront. This type of bar is best for serious off-road driving where you need maximum stability. If you put this on a street vehicle, it will ruin all of your cornerings and your ride quality will be severely compromised. This bar is extremely common for trucks that are used in competition or even just to make a grocery-getting vehicle more stable off-road.

The Bar With Two Ends

Also called the parallel or H link, this one will fit on any car with independent front suspension and 4wd where you need a bit more control of your sway but not as much as the triangulated bar will give you. It can also be used on cars with solid axle front ends, but I wouldn’t recommend it since your car’s handling won’t be perfect and you may get some “clunking” due to the geometry of the sway bar when going over bumps in the road.

The Adjustable Bar

Also called the progressive link it is only good for cars with solid axle front ends where you don’t need much sway control but would like to adjust how stiff your ride is and when. It can be used on any type of car, but there are other bars that will do what this one does better.

The Bar With Two End Links

Another name is an H frame. It is similar to the one with two ends, but it attaches only at the ends. It’s best for cars that only need minimal sway control, have a solid axle upfront, and don’t mind sacrificing some handling in order to get it.

Three Bar Kits

are made by combining any of the bars above and then adding a center bar to the mix so that all of your axles get equal sway control. The three bars are attached at their ends and usually only via end links instead of using bushings as most bars do. This type is best for serious off-road driving because it provides maximum stability on and off the road.

Four Bar Kits

are made by combining any of the bars above and adding two center bars (which are attached to each other, not the ends) to your sway bar system. This type is best for cars that will be doing more on-road than off-road driving because it gives a nice balance between handling and stability.

Urethane Bushing Style

This sway bar kit can be used on any type of car, so long as you don’t mind the extra noise that it may create.

Rubber Bushing Style

This last sway bar kit is best for cars that need a lot of sway control and either drive mostly on-road or off-road but not both.

Do Antirock Sway Bars Limit Flex?

You must also know the difference between “maximum articulation” and “useful flex” as they commonly encountered off-roading situations.

Maximum articulation, as the name suggests, is designing how much one can flex the suspension from the standard setup. Usually, maximum articulation gives really great show-off pictures with the tires in the air.

Quick disconnects are really helpful as they completely disconnect the sway bar from the axle. But usually, the maximum articulation results in no weight on the tire and hence no traction on the dropped tire as the spring is completely unseated.

Useful flex: Useful flex means to flex but also has traction between the tires and the ground. Of course, the traction still depends upon the surface condition, suspension setup, load distribution, and tires along with other variables.

The anti-rock sway bars would increase your vehicle’s articulation and also save you the hassle of connecting sway bars once you’re done with the trip. Usually, the anti-rock sway bars are made of treated steel ensuring much-needed high durability.

Those who have installed anti-rock sway bars are surprised at the control it brings while moving over terrains. While moving towards holes, the jeep instead of swaying towards the side, chassis would remain stable while tires would drop down in a more controlled manner while also providing greater traction.

What Are Antirock Sway Bar Components?

Anti-rock sway replaces the vehicle’s stock bars and once installed, they need not be disconnected for offroad use. A standard anti-rock sway bar containing the following components:

- Sway bar

- Semi-gloss black powder coated bolt-on steel frame brackets

- Bushings

- Semi-gloss black powder-coated arms

- Adjustable length sway bar links

- Bolts into existing holes in the bottom of the frame rail and attach to the stock mounts on the vehicle’s axle housing

Though antirock sway bar kits are available over the internet to order and do self-installation. Numerous videos are available over the internet for your guidance and one also needs not do any drilling for installation but it’s recommended to use the service of professionals. If you are buying online, do read some reviews from other buyers and verify the warranty period of the product.

An anti-sway bar is a suspension device that works to reduce body roll by connecting the left and right sides of a car. It does this by trying to keep both wheels from moving sideways at the same time which helps correct for oversteer or understeer conditions. This reduces tire wear as well as improves handling performance on turns.

They’re most commonly used in race cars where they are often adjustable so you can change their stiffness according to your preference or track condition. You might have seen them if you’ve ever watched any racing series like NASCAR, Formula One Racing, Indy Car Series, etc., but if not then it’s likely because they’re only installed onto high-end models with heavy suspensions such as SUVs,

Thanks for reading and stay dirty

![The 16 Most Aggressive All Terrain Tires [2022] reall aggressive all terrain tires on a Jeep](https://149868043.v2.pressablecdn.com/wp-content/uploads/2020/03/slide1-e1585156691843-300x150.jpg)